PIAA Round LED Driving and Fog Lights - led light fog

Our team of scientists and engineers work to understand your challenges. We then test, experiment, and invent to provide the best possible solutions.

1. Fastened to a hot product by nailing, wiring, or welding2. High-temperature tags withstand up to 1,800°F (982°C)3. Medium-temperatures tags withstand up to 900°F (482°C)

RepairTags

1. The only tag that stands up to atmospheric annealing ovens and cycles of long, high heat 2. Designed specifically for forges and foundries 3. Withstands temperatures of 1,800°F (982°C) for up to 48 hours and multiple heat cycles

1. Intended to track materials that are heat treated in oxygen-free furnaces 2. For use with carbon steel, stainless steel, copper, and exotic alloys 3. Withstands temperatures of 1,800°F (982°C) for two hours 4. Withstands temperatures of 1,600°F (871°C) for 48 hours

1. Resistant to heat, chemical, and environmental exposure in metal rod and wire processing 2. Text or barcode remains readable even after pickling and hot acid baths

These durable tags get applied immediately after casting or before hot processing such as annealing or pickling. They withstand hostile temperatures, weather, and chemicals. With a wide variety of attachment options available, InfoSight’s industrial tags can reduce — and in some cases eliminate — unsafe handling.

InfoSight’s fabricator tags simplify component tracking, whether inside a fab-shop or outside for galvanizers, painters, and powder coaters. Strong metal tags reduce the risk of misplacing valuable assets. Special coatings ensure readability after finishing and simplify shipping all the way to the building site. Barcodes make it easy to interface with your design and construction software.

1. Intended for applications where high-value assets require long-term identification 2. Flexible, self-adhesive labels can be cut to any shape or size 3. Resistant to sunlight, scratching, tampering, caustic power washing, solvents, brake fluid, transmission fluid, motor oil, and antifreeze

Out of Service Tag

1. Intended to track materials that are heat treated in oxygen-free furnaces 2. For use with carbon steel, stainless steel, copper, and exotic alloys 3. Withstands temperatures of 1,800°F (982°C) for two hours 4. Withstands temperatures of 1,600°F (871°C) for 48 hours

1. The only tag that stands up to atmospheric annealing ovens and cycles of long, high heat 2. Designed specifically for forges and foundries 3. Withstands temperatures of 1,800°F (982°C) for up to 48 hours and multiple heat cycles

1. Tag designed to survive Wheelabrators and shot blasting 2. Withstands cleaning, acid wash, ablative bead, and shot blasting processes 3. Resists common paints, water, solvent, epoxy, enamel, and lacquer

1. Specially coated stainless steel tag designed to withstand harsh environments indoors and outdoors 2. Low-cost identification solution for industrial equipment, such as valves, racks, pipes, lawnmowers, backhoes, and fixed assets 3. Long-term identification tag that survives temperatures up to 600°F (315°C) 4. Resistant to chemicals, solvents, acids, sunlight and U V exposure, and abrasion

CautionTags

The more moving parts your operation has, the more traceability impacts your efficiency, safety, and profitability. In-process asset tags from InfoSight keep track of your products and assets, while streamlining compliance and maintenance operations. With a wide variety of available attachment options, you can inventory everything from individual fixed assets to storage bins for reliable identification.

From hospitals and laboratories to steel mills and offshore oil rigs, InfoSight’s identification solutions meet tracking and traceability needs all over the world.

InfoSight offers special-purpose identification tags for nearly every application. Whether you need labels that stand up to chemical exposure, attach to precast concrete, or streamline operations in anatomical laboratories, InfoSight has you covered. We’re constantly diversifying our tag offerings, and we continue to develop identification solutions for niche and on-demand applications.

1. Flexible, cost-effective way of meeting the EPA’s leak detection and repair (LDAR) requirements 2. Highly resistant to rust, sunlight, fading and weathering 3. Available in a variety of colors to simplify identification tagging and updating 4. LDAR TwinTag™ available for readability on both sides

1. U.S. and Foreign patents pending2. Enables an identification process that is three times faster3. Survives the entire galvanizing process

1. Aluminum tags resistant to high temperatures, acids, oils, cleaning solutions, fading, and UV rays 2. Designed to be affixed to molten aluminum ingots and logs by direct casting or nailing, wiring, and stud welding 3. Survives the heat of homogenizing furnaces up to 1,000°F (538°C)

1. Remains readable through powder coating, including the high-temperature curing process 2. Survives temperatures up to 600°F (316°C) and common chemical processes 3. Abrasion and chemical resistant 4. Highly resistant to sunlight and fading

1. First-ever tag to survive the entire galvanizing process 2. One tag provides traceability from the fabricator to the end user 3. Durable identification increases efficiency and reduces paperwork

1. Flexible, cost-effective way of meeting the EPA’s leak detection and repair (LDAR) requirements 2. Highly resistant to rust, sunlight, fading and weathering 3. Available in a variety of colors to simplify identification tagging and updating 4. LDAR TwinTag™ available for readability on both sides

1. Identification tag that attaches flush to poured concrete castings 2. Withstands rain, washing, rust, and temperatures up to 1,000°F (538°C) 3. Text and barcodes remain readable through curing, coating, yard stacking, shipping, and installation 4. Reduces identification errors during transportation and onsite assembly

Our tags can be printed uniquely or uniformly with text, logos, and multiple barcodes. They are available nicked and notched in varying lengths for easy break-off. We also offer a wide variety of attachment options to fit your application.

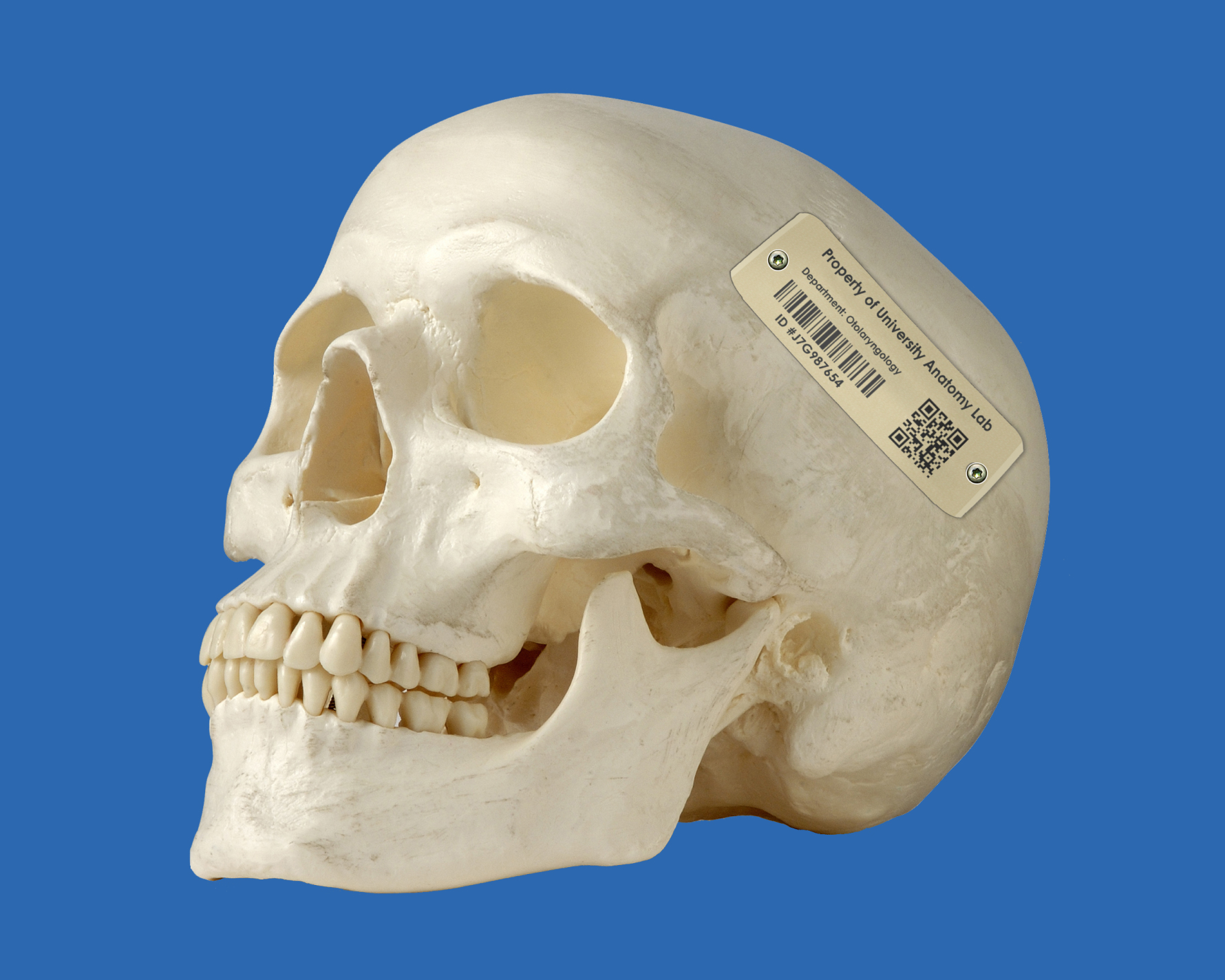

1. Provides identification and security during anatomical specimen preservation 2. Resistant to a wide spectrum of disinfectants, germicides, and preservatives used in medical and scientific communities 3. Survives exposure to formalin and glutaraldehyde as well as other chemicals and organic cleansers

1. Designed to identify assets and components in the alumina industry and in processes that include exposure to high pH environments 2. Combines durability and rigidity with caustic survivability 3. Chemical resistant, abrasion resistant, and heat resistant up to 200°F (93°C)

1. Scuff-proof metal identification labels made from anodized aluminum 2. Specifically designed to survive in abrasive, chemical, and high temperature environments up to 1,000°F (538°C) 3. Available in a variety of colors, depending on the environment

1. Heavy-duty stainless steel tag resistant to chemicals, mild abrasion, UV exposure and heat up to 1,000°F (538°C) 2. Withstands most common solvents and cleaners as well as most weather conditions 3. Adaptable to industrial adhesives

Warning: Do not rely solely on this sign to discourage persons with AD from opening or exiting through dangerous doorways, as signs can always be ignored, not seen or not understood.

DangerTags

Many of InfoSight’s durable metal tags are available for on-demand printing with alphanumeric text, graphics, logos, and 1D / 2D barcodes. We’ll guide you through the tag selection process, including creating a tag design and recommend the best tag for your needs.

1. Tag designed to survive the acid prep, pre-wash, painting, and curing process for fabricated steel 2. Made of weather-resistant metal substrate for durability and rough handling 3. Resistant to prewash, acids, painting, and high-temperature paint curing up to 1,000°F (538°C)

Whether you need to meet unique identification (UID) requirements or label a curved asset, we have a tag for the job. With a variety of identification solutions built to withstand industrial and outdoor environments, we’ll help you choose the right tags for your operations, so you never lose track of your valuable fixed assets.

1. Fastened to a hot product by nailing, wiring, or welding 2. High-temperature tags withstand up to 1,800°F (1,000°C) 3. Medium-temperatures tags withstand up to 900°F (482°C)

1. Stainless steel substrate with coating on both sides 2. Designed and manufactured to withstand the rigors of pickling (sulphuric or hydrochloric) and annealing up to 1,800°F (982°C) for 2 hours

13322766566

13322766566